Company Name:

Incubation Round:

Application Track:

Proposed by:

COFARES

Data Provider:

COFARES

Challenge Name:

Product Description

As the first step toward extracting printed text information and data matrix code from a series of boxes, the boxes in the input image are detected using our box detection algorithm. Then, the printed text information is extracted using our text detection and OCR algorithms. Next, the data matrix codes are detected using our data matrix detection algorithm. Then, the serial code in the data matrix is recognized using our data matrix recognition algorithm. Finally, if the printed serial numbers are not equal to the data matrix, an alarm will be sent to the supervisor along with the location of the boxes that have any kind of occlusion.

These deep learning-based solutions are designed to operate efficiently on CPU-based systems, making the overall process accessible to a wider range of hardware configurations. By employing a combination of text detection, OCR, data matrix detection, and data matrix recognition algorithms, the challenge of extracting and matching printed text information and data matrix codes from a series of boxes is solved effectively.

Usage of Standards for data interoperability:

This project adheres to the following data interoperability standards to ensure seamless communication, data exchange, and integration across various systems and components:

- ISO/IEC 15415 – Barcode Print Quality Test Specification (2D Symbols): This standard provides guidelines for the print quality of data matrix codes. Our data matrix detection and recognition algorithms comply with this standard to ensure accurate and reliable extraction of information from the data matrix codes.

- GS1 DataMatrix: This is a standard developed by GS1, a global organization that develops and maintains standards for the supply chain industry. The GS1 DataMatrix is based on the ISO/IEC 16022 standard and is designed to encode product information, including GTIN (Global Trade Item Number), batch/lot number, and expiry date.

- QR Code: QR (Quick Response) code is a 2D barcode that is widely used for various applications, including marketing, payment, and authentication. It is standardized by ISO/IEC 18004 and can encode a wide range of data types, including text, URLs, and contact information.

- JSON (JavaScript Object Notation): JSON is a lightweight data interchange format that is easy to read and write. It is used in our project to store and exchange data between different components of the system. This facilitates easy integration and communication between the various algorithms and modules.

- REST (Representational State Transfer) API: The RESTful API standard is used to establish communication between our system and any external systems, such as a supervisor’s computer or a centralized database. This ensures that our solution can seamlessly exchange information with other systems and integrate with existing infrastructure.

- OPC UA (Open Platform Communications Unified Architecture): As an industry-specific standard for data exchange in industrial automation systems, OPC UA is used to ensure compatibility with other devices and systems in the manufacturing environment. This standard allows our solution to send alarms, notifications, and box location data to a supervisory system or control center in a standardized format.

- Standard image formats such as JPEG (Joint Photographic Experts Group), PNG (Portable Network Graphics), TIFF (Tagged Image File Format), BMP (Bitmap), and MPEG-7 (Moving Picture Experts Group) for multimedia content description.

By adhering to these standards, our project ensures seamless data interoperability, compatibility with various systems, and efficient communication between different components of the solution.

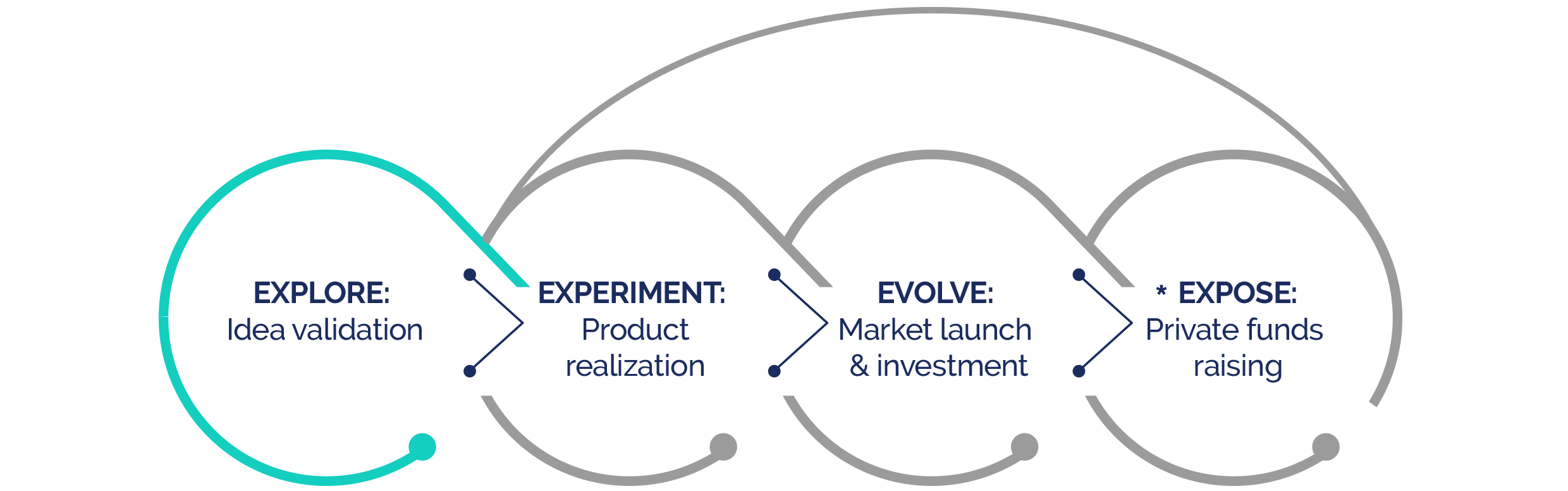

*Expose phase is open to all Experiment phase teams

Location:

Sector:

Website:

Company maturity:

Investment level:

Funding raised:

Collaboration opportunity:

Company Description

INTRASENSORS BV, as a Belgian tech-start up, founded in 2020 to develop and create intelligent sensors to help people around the globe live in a safe and smart environment. This company was established to bring together the researchers conducted over 15 years in the form of university projects and give it a legal and commercial personality. It is set up based on developing smart and innovative solutions that are required for state-of-the-art intelligent sensors powered by AI and machine learning.

Now, INTRASENSORS BV has a product portfolio based on ICT and AI. It has also focused on smart sensors for medical solutions and healthcare. Thanks to professional employees in analytical software development and processing all kinds of data, especially related to medicine, the company is scrimmaging with medical platforms and their big data as well as analysing them.

Karim M.P. Aghdam

He held Ph.D. in Electrical Engineering from KU Leuven with emphasis on intelligent sensors. Now, he is a visiting professor at KU Leuven, and Founder of the INTRASENSORS.

Hasan Bahari

As an AI/ML engineer, he holds a Ph.D. in engineering at KU Leuven in collaboration with MIT and is an expert in big data and image processing.

Sadegh Sarvi

As a business analyst and project manager, he held his Doctor of Business Administration (DBA). He has collaborated as Market advisor and PMO in INTRASENSORS.